Rubber Washers

Thomas A. Caserta has manufactured rubber washers for many diverse and demanding industries for over 60 years. A rubber washer is a small flat rubber ring used on fasteners and in mechanical devices. Rubber washers are used to seal fluids, prevent leaks, dampen vibration and protect surfaces.There are many performance specifications that are important for rubber washers. Many different rubber materials can be used in the production of rubber washers to achieve the desired performance. Some of the common materials used are EPDM, Neoprene, Nitrile, SBR, Silicone, and Viton. Different materials are better suited to different applications depending on factors such as temperature resistance, fluid resistance, chemical resistance, ozone resistance, and abrasion resistance. Thus, it is important to choose the correct material for rubber washers to suit your application. Our engineers are always available for any technical assistance you may require.

We manufacture rubber washers to any size and material specification. We also custom manufacture rubber washers with special nibs on the I.D. (inside diameter) designed for automated screw assembly equipment.

Thomas A. Caserta, Inc. utilizes several different methods to consistently produce the highest quality rubber washers for your application depending on the size and tolerance required. Our methods include high speed on-demand cut rubber washers, lathe cut rubber washers, guillotine cut rubber washers, die cut rubber washers, water jet cut rubber washers, and hand cut rubber washers. /Asset/1357.jpg

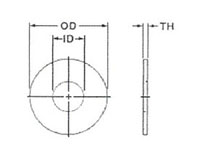

Standard Hose Washer

Our durable EPDM rubber washers create a reliable, leak-free seal between rubber hoses and accessories. Ideal for garden hoses and washing machines or any similar applications

Material: Black EPDM Rubber

OD = 1.00 +/- .020

ID = .625 +/- .015

TH = .125 +/- .010

Item No. 1-625-125

Rubber Gaskets

A rubber gasket is a type of rubber washer that is typically placed between two surfaces where there is a requirement to stop leakage of either liquid or air. Rubber gaskets are used extensively in the manufacturing of appliances and machinery, and many other industries.There are many performance specifications that are important for rubber gaskets. Many different rubber materials can be used in the production of rubber gaskets to achieve the desired performance. Some of the common materials used are EPDM, Neoprene, Nitrile, SBR, Silicone, and Viton. Different materials are better suited to different applications depending on factors such as temperature resistance, fluid resistance, chemical resistance, ozone resistance, and abrasion resistance. Thus, it is important to choose the correct material for rubber gaskets to suit your application. Our engineers are always available for any technical assistance you may require.

We manufacture rubber gaskets to any size and material specification. We specialize in manufacturing precision lathe cut rubber gaskets that require very close tolerance. We also manufacture adhesive backed rubber gaskets with a PSA (pressure sensitive adhesive) on one side.

We utilize several different methods to consistently produce the highest quality rubber gaskets for any application. Our methods include lathe cut rubber gaskets, die cut rubber gaskets and water jet cut rubber gaskets. Thomas A. Caserta, Inc. was founded in 1948 and has been a leading global supplier of rubber gaskets for over 60 years. /Asset/1353.jpg

Rubber Bushings

Thomas A. Caserta, Inc. has been a leading manufacturer of straight rubber bushings for many industries and applications since 1948. A rubber bushing is used to provide an interface between two parts and dampen energy or vibration through the bushing. Rubber bushings are used as vibration isolators, abrasion resistors, shock absorbers, and as seals for wires, pipes and rods.There are many performance specifications that are important for rubber bushings. Many different rubber materials can be used in the production of rubber bushings to achieve the desired performance. Some of the common materials used are EPDM, Neoprene, Nitrile, SBR, Silicone, and Viton. Different materials are better suited to different applications depending on factors such as temperature resistance, fluid resistance, chemical resistance, ozone resistance, and abrasion resistance. Thus, it is important to choose the correct material for rubber bushings to suit your application. Our engineers are always available for any technical assistance you may require.

Thomas A. Caserta, Inc. manufactures straight rubber bushings to any size and material specification. We employ several different methods to consistently produce the highest quality rubber bushings. Our methods include lathe cut rubber bushings, on-demand cut rubber bushings, water jet cut rubber bushings, and hand cut rubber bushings. /Asset/1352.jpg

Rubber Tubing and Cord

Thomas A. Caserta has been a leading extruder of rubber tubing and cord for many industries for over 60 years. Rubber tubing is an unreinforced flexible hose used to move liquids or gases. Rubber tubing is used in many industries for a wide variety of applications. Rubber tubing is commonly used in the aerospace, pharmaceutical, chemical, electrical, medical, and food processing industries. Rubber cord is a solid rubber tube that does not have a hole in the center. Rubber cord can be used to fabricate large custom o-rings or as a gap seal on machinery and other equipment.As with any rubber product, there are many performance specifications that are important for rubber tubing. Many different rubber materials can be used in the production of rubber tubing to achieve the desired performance. Some of the common materials used are EPDM, Neoprene, Nitrile, SBR, Silicone, and Viton. Different materials are better suited to different applications depending on factors such as temperature resistance, fluid resistance, chemical resistance, ozone resistance, and abrasion resistance. Thus, it is important to choose the correct material for rubber tubing to suit your application. Our engineers are always available for any technical assistance you may require.

Thomas A. Caserta, Inc. can extrude rubber tubing to any size and material specification. We can supply rubber tubing or cord on spools or coiled and boxed. We also can cut rubber tubing and rubber cord to length that can be used as rubber spacers, rubber standoffs, and rubber discs. We utilize state-of-the-art extrusion equipment to consistently produce the highest quality rubber tubing and rubber cord. /Asset/1350.jpg

Silicone Tubing

Silicone rubber tubing is a flexible unreinforced rubber hose that is widely used in the medical industry. Silicone rubber has many unique characteristics such as medical grades and resistance to extreme temperatures. Silicone tubing is extremely elastic and resistant to the effects of weather, U.V., radiation and ozone. These properties make silicone tubing a very useful resource for the aerospace and electrical industries as well.

Thomas A. Caserta, Inc. manufactures silicone tubing in a large variety of specifications and colors to meet your application's requirements. We extrude silicone tubing in platinum-cured, peroxide-cured, low cost general purpose and many other grades. We can supply silicone tubing on spools or coiled and boxed. All our extrusion and tooling is done in house in our sate-of-the-art facility to consistently produce only the highest quality silicone tubing.

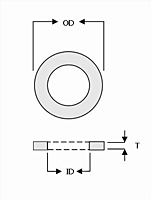

Standard EPDM Rubber Washers

(19) Our standard EPDM rubber sealing washers create a reliable seal against air, water, and steam. These rubber washers are perfect for outdoor use and resistant to ozone and weathering. They also may be used to dampen vibration or reduce wear and marring. /Asset/5498_Washer.jpg

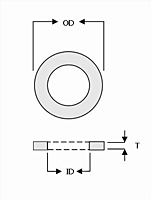

Standard Neoprene Rubber Washers

(19) Our standard Neoprene rubber sealing washers create a reliable static seal. These Neoprene rubber washers are resistant to freons and mild acids. They also have moderate resistance to oil, ozone, and water. /Asset/5498_Washer.jpg

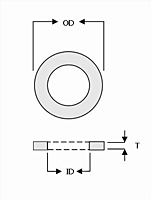

Standard Nitrile (Buna-n) Rubber Washers

(19) Our standard Nitrile (Buna-n) rubber sealing washers create a reliable static seal. These Nitrile rubber washers are ideal for applications that require resistance to petroleum products, oil, or water.. /Asset/5498_Washer.jpg

High Speed On-Demand Rubber Cutting Services

Our high speed on-demand cutters are a very cost effective method of producing rubber washers and rubber gaskets. These “flying knife” type cutters cut rubber tubing into rubber washers and rubber gaskets at high production speeds with minimal waste of material.Thomas A. Caserta, Inc. has our on-demand cutters custom made with intermittent stop-and-go technology that provides an efficient cutting process of up to 800 cuts per minute. Due to the brief stop, high length accuracy and precise right-angled cuts are achieved. Our high speed on-demand cutting services offer fast turnaround time, precise tolerance, high production volume, and prototype and short run production.

We utilize our high speed on-demand cutters to consistently produce high quality, precision cut, rubber washers, rubber gaskets, rubber bushings, rubber spacers, rubber stand-offs, and rubber discs. /Asset/On-Demand-Cutter.jpg

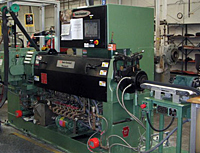

Custom Rubber Lathe Cutting Services

Lathe cutting rubber washers and rubber gaskets is the process of inserting a mandrel into an extruded rubber tube and cutting the finished dimension with a knife while the mandrel is being turned at high speed in a lathe. We use state-of-the-art lathes and grinding equipment to finish the outer surface to precise tolerance.Some of the advantages of lathe cutting are no tooling cost, minimal waste, no flash, no die-cut concavity (hour-glassing), and an excellent static face sealing surface.

Thomas A. Caserta, Inc. has been a leading manufacturer of lathe cut rubber gaskets, rubber washers, rubber seals, rubber bushings, rubber sleeves, and rubber rollers for over 60 years. /Asset/Lathe-Cutting-Machine.jpg

Die Cutting and Water Jet Cutting Services

Die cutting and water jet cutting is the manufacturing process of cutting materials into predefined shapes and sizes from sheet or roll stock to produce custom parts.Thomas A. Caserta, Inc. uses several types of die cutting methods including steel rule die cutting, high speed rotary die cutting and water jet cutting. The method used can vary, depending on such factors as material, quantity, and shape of part. We manufacture parts in a wide variety of non-metallic materials and sizes with 100% repeatability. Our custom die cutting and water jet cutting services offer fast turnaround time, precise tolerance, high production volume, and prototype and short run production.

Thomas A. Caserta, Inc. has been a leading manufacturer of high quality custom made die cut and water jet cut rubber gaskets, rubber washers and other rubber components since 1948. /Asset/Die-Cutting-Machine.jpg

High Speed Guillotine Rubber Washer Cutting Services

Our high speed guillotine cutters are a very efficient and cost effective method of manufacturing rubber washers. With multiple tube cutting capabilities, these machines can produce up to 9,000 rubber washers per minute.Thomas A. Caserta, Inc. has all our guillotine cutters custom made to our own proprietary design. These machines employ intermittent stop-and-go technology that provides an efficient and accurate cutting process. All our guillotine cutters are equipped with high carbon steel blades to ensure precise right-angled cuts and tolerance accuracy.

These machines produce high quality, precision cut rubber sealing washers at very economical production speeds. /Asset/guillotine-cutter.jpg

Custom Rubber Extrusion Services

Our rubber extrusion department extrudes custom rubber tubing and rubber cord to your specification. The process of extrusion involves forcing uncured rubber through a die to form a desired, uniform, cross-sectional size and shape before curing.Thomas A. Caserta, Inc. utilizes our sate-of-the-art extruders to produce high quality rubber tubing and rubber cord in a wide variety of materials. Our rubber extruders are equipped with the latest development in control systems and screw and barrel design. All our dies are made in-house and usually at no cost to the customer, which means fast turnaround times for prototype as well as production run extrusions.

We can supply are extruded rubber tubing and rubber cord on spools, cut in straight lengths, or coiled and boxed. We also cut rubber tubing and rubber cord to desired length to form rubber washers, rubber bushings, rubber spacers, rubber gaskets, rubber stand-offs, and rubber discs. /Asset/EXTRUDER-2.jpg